This article has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these messages)

|

Epitaxy (prefix epi- means "on top of") refers to a type of crystal growth or material deposition in which new crystalline layers are formed with one or more well-defined orientations with respect to the crystalline seed layer. The deposited crystalline film is called an epitaxial film or epitaxial layer. Epitaxial growth and semiconductor device fabrication are technologies used to develop stacked crystalline layers of different materials with specific semiconductor properties on a crystalline substrate, commonly silicon or silicon carbide materials, to achieve the desired performance of the microelectronic devices, such as transistors and diodes. The crystal structure of these layers is with high density of imperfections, such as dislocations and stacking faults. Therefore the microelectronic engineers and technologists have developed different techniques to eliminate or minimize the density of these structural defects in order to improve the microelectronic devices operation . One such approach is the Selective Area Growth technology.

Lateral epitaxial overgrowth (LEO) along with pendeo-epitaxy (PE) are selective area growth (SAG) techniques, developed in the late 1990s and early 2000s for epitaxial growth of wide bandgap semiconductor materials, such as gallium nitride: gallium nitride (GaN) on silicon carbide (SiC) substrate.[1][2],[3][4][2][5][6] GaN on sapphire (Al2O3) substrate,[7][8] and GaN on silicon (Si) substrate.[9][10] Epitaxial GaN is relevant to a semiconductor device technology important in microelectronics and chip manufacturing for development of high-power, high frequency, high temperature electronic devices.[11][12][13][14] LEO and PE are technologies that are not limited to the wide bandgp GaN materials. Conventional epitaxial growth techniques of GaN on SiC, sapphire and Si substrate are known to produce high density of structural defects,[15][16][17] mainly edge and screw dislocations and stacking faults, in the order of 109-1010 cm-2. PE and LEO, the latter also referred to epitaxial lateral overgrowth (ELO), are known to enable two to four orders of magnitude lower density of dislocations, compared to conventional growth,as revealed via transmission electron microscopy [3]. Having device layers of low defect density enables improved device characteristics and performance[18][19]

Lateral epitaxial overgrowth (LEO)

editLEO involves growing a seed GaN layer of the material on a substrate, then etching a patterned mask on the surface of the seed layer, commonly silicon dioxide or silicon nitride, leaving some GaN seed windows exposed that act as crystallographic template for the subsequent growth of the GaN layer (Figure 1). The new LEO film grows simultaneously from the GaN windows both vertically and at the same time extends laterally over the mask, forming wings of much lower density of structural defects (mostly treading dislocations). The wings can merge together to form a continuous GaN film, or remain separated by seams[9]. Notably LEO process drastically reduces the defects in the crystal structure of the laterally grown areas by filtering them out at the mask interface. LEO can be performed from the vapor phase, depending on the material and the growth conditions via epitaxial growth techniques such as metalorganic vapour-phase epitaxy (MOCVD) or hydride vapour-phase epitaxy (HVPE).

Pendeo-epitaxy

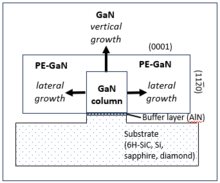

editInitially PE was developed as an alternative technology and complementary approach to lateral epitaxial overgrowth (LEO) of GaN on SiC substrate[3][4]. Pendeo-epitaxy of GaN involves growing a continuous GaN film, commonly with high density of dislocations, as a seed layer on a substrate (SiC, sapphire or Si), then etching away portions from the GaN film (seed layer) thus leaving GaN seed stripes or columns, separated by trenches. The subsequent PE layer grows simultaneously from the tops and the side walls of the GaN stripes or columns (Figure 2). Thus, the top and the side walls of these columns act as homoepitaxial seed layers, which act as crytallographic templates for the subsequent vertical and lateral growth of continuous PE GaN layers. The regions of lateral growth are again with two to four orders of magnitude lower density of dislocations. Importantly, the film grows laterally from the side walls of the columns and extends horizontally over the trenches without touching the initial seed layer, forming wings of low crystallographic defect density[5]. Hence pendeo-epitaxy, a term from Latin pendare, meaning to hang down, suspend. The wings can merge to form a continuous film or remain separated by seams. As with LEO, pendeo-epitaxy mechanism reduces the crystallographic defects in the film by avoiding the direct contact with the substrate, eliminating the lattice mismatch and the thermal mismatch stress/strain. Pendeo-epitaxy is mainly performed from the vapor phase via MOCVD and HVPE, and initially is used for growing gallium nitride (GaN) microelectronic device structures.

In the case of GaN material system, LEO and PE technology was initiated in the late nineties and early 2000s in Prof. R.F. Davis group at NCSU. The PE and LEO technologies are not limited to the development of low defect density wide bandgap GaN layers, important for the microelectronics industry, but also for many other epitaxial materials systems (Si, SiC, diamond etc.). Modeling of the LEO and PE growth processes reveals improved stress/strain characteristics[20] and the concomitant improved characteristics in the microelectronic devices fabricated thereby. The strong microelectronics relevance of PE and LEO technologies to enable low density of dislocations in the semiconductor layers was documented in numerous patents.[21][22][23][24][25][26][27]

References

edit- ^ Zheleva, Tsvetanka S.; Nam, Ok-Hyun; Bremser, Michael D.; Davis, Robert F. (1997-10-27). "Dislocation density reduction via lateral epitaxy in selectively grown GaN structures". Applied Physics Letters. 71 (17): 2472–2474. Bibcode:1997ApPhL..71.2472Z. doi:10.1063/1.120091. ISSN 0003-6951.

- ^ a b Nam, Ok-Hyun; Bremser, Michael D.; Zheleva, Tsvetanka S.; Davis, Robert F. (1997-11-03). "Lateral epitaxy of low defect density GaN layers via organometallic vapor phase epitaxy". Applied Physics Letters. 71 (18): 2638–2640. Bibcode:1997ApPhL..71.2638N. doi:10.1063/1.120164. ISSN 0003-6951.

- ^ a b Zheleva, Tsvetanka S.; Nam, Ok-Hyun; Ashmawi, Waeil M.; Griffin, Jason D.; Davis, Robert F. (2001-02-01). "Lateral epitaxy and dislocation density reduction in selectively grown GaN structures". Journal of Crystal Growth. 222 (4): 706–718. Bibcode:2001JCrGr.222..706Z. doi:10.1016/S0022-0248(00)00832-0. ISSN 0022-0248.

- ^ a b Zheleva, Tsvetanka S.; Smith, Scott A.; Thomson, Darren B.; Linthicum, Kevin J.; Rajagopal, Pradeep; Davis, Robert F. (April 1999). "Pendeo-epitaxy: A new approach for lateral growth of gallium nitride films". Journal of Electronic Materials. 28 (4): L5–L8. Bibcode:1999JEMat..28L...5Z. doi:10.1007/s11664-999-0239-z. ISSN 0361-5235.

- ^ a b Davis, Robert F.; Gehrke, T; Linthicum, K.J.; Rajagopal, P; Roskowski, A.M.; Zheleva, T.; Preble, Edward A.; Zorman, C.A.; Mehregany, M.; Schwarz, U.; Schuck, J.; Grober, R. (2001). "Review of Pendeo-Epitaxial Growth and Characterization of Thin Films of GaN and AlGaN Alloys on 6H-SiC(0001) and Si(111) Substrates". MRS Internet Journal of Nitride Semiconductor Research. 6. doi:10.1557/S1092578300000260. ISSN 1092-5783.

- ^ Zheleva, Tsvetanka S.; Smith, Scott A.; Thomson, Darren B.; Gehrke, Thomas; Linthicum, Kevin J.; Rajagopal, Pradeep; Carlson, Eric; Ashmawi, Waeil M.; Davis, Robert F. (1999-12-01). "Pendeo-Epitaxy - A New Approach for Lateral Growth of Gallium Nitride Structures". MRS Internet Journal of Nitride Semiconductor Research. 4 (1): 275–280. doi:10.1557/S1092578300002581. ISSN 1092-5783.

- ^ Chichibu, S. F.; Marchand, H.; Minsky, M. S.; Keller, S.; Fini, P. T.; Ibbetson, J. P.; Fleischer, S. B.; Speck, J. S.; Bowers, J. E.; Hu, E.; Mishra, U. K.; DenBaars, S. P.; Deguchi, T.; Sota, T.; Nakamura, S. (1999-03-08). "Emission mechanisms of bulk GaN and InGaN quantum wells prepared by lateral epitaxial overgrowth". Applied Physics Letters. 74 (10): 1460–1462. Bibcode:1999ApPhL..74.1460C. doi:10.1063/1.123581. ISSN 0003-6951.

- ^ Lahrèche, H; Vennéguès, P; Beaumont, B; Gibart, P (1999-09-01). "Growth of high-quality GaN by low-pressure metal-organic vapour phase epitaxy (LP-MOVPE) from 3D islands and lateral overgrowth". Journal of Crystal Growth. 205 (3): 245–252. Bibcode:1999JCrGr.205..245L. doi:10.1016/S0022-0248(99)00299-7. ISSN 0022-0248.

- ^ a b Davis, Robert F.; Gehrke, T.; Linthicum, K. J.; Zheleva, T. S.; Preble, E. A.; Rajagopal, P.; Zorman, C. A.; Mehregany, M. (2001-05-01). "Pendeo-epitaxial growth of thin films of gallium nitride and related materials and their characterization". Journal of Crystal Growth. Proceedings of the 12th American Conference on Crystal Growth and Epitaxy. 225 (2): 134–140. Bibcode:2001JCrGr.225..134D. doi:10.1016/S0022-0248(01)00836-3. ISSN 0022-0248.

- ^ Feltin, Eric; Beaumont, B.; Laügt, M.; de Mierry, P.; Vennéguès, P.; Lahrèche, H.; Leroux, M.; Gibart, P. (2001-11-12). "Stress control in GaN grown on silicon (111) by metalorganic vapor phase epitaxy". Applied Physics Letters. 79 (20): 3230–3232. Bibcode:2001ApPhL..79.3230F. doi:10.1063/1.1415043. ISSN 0003-6951.

- ^ Woo, Kelly; Bian, Zhengliang; Noshin, Maliha; Perez Martinez, Rafael; Malakoutian, Mohamadali; Shankar, Bhawani; Chowdhury, Srabanti (2024-04-01). "From wide to ultrawide-bandgap semiconductors for high power and high frequency electronic devices". Journal of Physics: Materials. 7 (2): 022003. Bibcode:2024JPhM....7b2003W. doi:10.1088/2515-7639/ad218b. ISSN 2515-7639.

- ^ La Via, Francesco; Alquier, Daniel; Giannazzo, Filippo; Kimoto, Tsunenobu; Neudeck, Philip; Ou, Haiyan; Roncaglia, Alberto; Saddow, Stephen E.; Tudisco, Salvatore (June 2023). "Emerging SiC Applications beyond Power Electronic Devices". Micromachines. 14 (6): 1200. doi:10.3390/mi14061200. ISSN 2072-666X. PMC 10300968. PMID 37374785.

- ^ Pearton, S. J.; Zolper, J. C.; Shul, R. J.; Ren, F. (1999-07-01). "GaN: Processing, defects, and devices". Journal of Applied Physics. 86 (1): 1–78. Bibcode:1999JAP....86....1P. doi:10.1063/1.371145. ISSN 0021-8979.

- ^ Kum, Hyun; Lee, Doeon; Kong, Wei; Kim, Hyunseok; Park, Yongmo; Kim, Yunjo; Baek, Yongmin; Bae, Sang-Hoon; Lee, Kyusang; Kim, Jeehwan (October 2019). "Epitaxial growth and layer-transfer techniques for heterogeneous integration of materials for electronic and photonic devices". Nature Electronics. 2 (10): 439–450. doi:10.1038/s41928-019-0314-2. ISSN 2520-1131.

- ^ Matthews, J. W.; Blakeslee, A. E. (1974-12-01). "Defects in epitaxial multilayers: I. Misfit dislocations". Journal of Crystal Growth. 27: 118–125. doi:10.1016/S0022-0248(74)80055-2. ISSN 0022-0248.

- ^ Matthews, J. W.; Blakeslee, A. E. (1975-07-01). "Defects in epitaxial multilayers: II. Dislocation pile-ups, threading dislocations, slip lines and cracks". Journal of Crystal Growth. 29 (3): 273–280. Bibcode:1975JCrGr..29..273M. doi:10.1016/0022-0248(75)90171-2. ISSN 0022-0248.

- ^ Matthews, J. W.; Blakeslee, A. E. (1976-02-01). "Defects in epitaxial multilayers: III. Preparation of almost perfect multilayers". Journal of Crystal Growth. 32 (2): 265–273. Bibcode:1976JCrGr..32..265M. doi:10.1016/0022-0248(76)90041-5. ISSN 0022-0248.

- ^ Nakamura, Shuji (1998-08-14). "The Roles of Structural Imperfections in InGaN-Based Blue Light-Emitting Diodes and Laser Diodes". Science. 281 (5379): 956–961. doi:10.1126/science.281.5379.956. ISSN 0036-8075. PMID 9703504.

- ^ Webb, Colin E., ed. (2004). Handbook of laser technology and applications. Bristol: Institute of Physics. ISBN 978-0-7503-0607-2.

- ^ Zheleva, Tsvetanka S.; Ashmawi, Waeil M.; Nam, Ok-Hyun; Davis, Robert F. (1999-04-26). "Thermal mismatch stress relaxation via lateral epitaxy in selectively grown GaN structures". Applied Physics Letters. 74 (17): 2492–2494. Bibcode:1999ApPhL..74.2492Z. doi:10.1063/1.123017. ISSN 0003-6951.

- ^ US 6570192B1, Davis, Robert; Nam, Ok-Hyun; Zheleva, Tsvetanka; Bremser, Michael, "Gallium nitride semiconductor structures including lateral gallium nitride layers", published 2003-05-27

- ^ US 6265289B1, Zheleva, Tsvetanka; Thomson, Darren; Smith, Scott; Linthicum, Kevin; Gehrke, Thomas; Davis, Robert, "Methods of fabricating gallium nitride semiconductor layers by lateral growth from sidewalls into trenches, and gallium nitride semiconductor structures fabricated thereby", published 2001-07-24

- ^ US 11251272B2, Li, Jizhong; Lochtefeld, Anthony J., "Lattice-mismatched semiconductor structures with reduced dislocation defect densities and related methods for device fabrication", published 2022-02-15

- ^ US 10374120B2, Atwater, Jr., Harry A.; Zahler, James M.; Morral, Anna Fontcuberta i; Pinnington, Tom; Olson, Sean, "High efficiency solar cells utilizing wafer bonding and layer transfer to integrate non-lattice matched materials", published 2019-08-06

- ^ US 8502263B2, Li, Jizhong; Lochtefeld, Anthony J., "Light-emitter-based devices with lattice-mismatched semiconductor structures", published 2013-08-06

- ^ US 7083679B2, Kiyoku, Hiroyuki; Nakamura, Shuji; Kozaki, Tokuya; Iwasa, Naruhito; Chocho, Kazuyuki, "Nitride semiconductor growth method, nitride semiconductor substrate, and nitride semiconductor device", published 2006-08-01

- ^ US 6818926B2, Koide, Norikatsu; Winner, Karl; Kuehn, Benjamin, "Method for manufacturing gallium nitride compound semiconductor", published 2004-11-16

This article needs additional or more specific categories. (November 2024) |