This article needs additional citations for verification. (February 2019) |

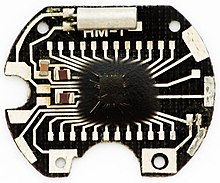

Chip on board (COB) is a method of circuit board manufacturing in which the integrated circuits (e.g. microprocessors) are attached (wired, bonded directly) to a printed circuit board, and covered by a blob of epoxy.[1] Chip on board eliminates the packaging of individual semiconductor devices, which allows a completed product to be less costly, lighter, and more compact. In some cases, COB construction improves the operation of radio frequency systems by reducing the inductance and capacitance of integrated circuit leads.

COB effectively merges two levels of electronic packaging: level 1 (components) and level 2 (wiring boards), and may be referred to as "level 1.5".[2]

Construction

editA finished semiconductor wafer is cut into dies. Each die is then physically bonded to the PCB. Three different methods are used to connect the terminal pads of the integrated circuit (or other semiconductor device) with the conductive traces of the printed circuit board.

Flip chip

editIn "flip chip on board", the device is inverted, with the top layer of metallization facing the circuit board. Small balls of solder are placed on the circuit board traces where connections to the chip are required. The chip and board are passed through a reflow soldering process to make the electrical connections.

Wire bonding

editIn "wire bonding", the chip is attached to the board with an adhesive. Each pad on the device is connected with a fine wire lead that is welded to the pad and to the circuit board. This is similar to the way that an integrated circuit is connected to its lead frame, but instead the chip is wire-bonded directly to the circuit board.[3]

Glob-top

editGlob-top is a variant of conformal coating used in chip-on-board assembly (COB). It consists of a drop of specially formulated epoxy[4] or resin deposited over a semiconductor chip and its wire bonds, to provide mechanical support and exclude contaminants such as fingerprint residues which could disrupt circuit operation. It is most commonly used in electronic toys and low-end devices.[5]

Flexible circuit board

editIn "tape-automated bonding", thin flat metal tape leads are attached to the semiconductor device pads, then welded to the printed circuit board.

In all cases, the chip and connections are covered with an encapsulant to reduce entry of moisture or corrosive gases to the chip, to protect the wire bonds or tape leads from physical damage, and to help dissipate heat.[2]

The printed circuit board substrate may be assembled into the final product, for example, as in a pocket calculator, or, in the case of a multi-chip module, the module may be inserted in a socket or otherwise attached to yet another circuit board. The substrate wiring board may include heat-dissipating layers where the mounted devices handle significant power, such as in LED lighting or power semiconductors. Or, the substrate may have low-loss properties required at microwave radio frequencies.

COB LED modules

editCOBs containing arrays of light-emitting diodes have made LED lighting more efficient. [6] LED COBs include a layer of silicone containing yellow Ce:YAG phosphor that encapsulates the LEDs and turns the blue light of the LEDs into white light. The COB is usually built on an aluminum PCB that provides good thermal conductivity to a heatsink. COB LEDs could be compared with multi chip modules or hybrid integrated circuits since all three can incorporate multiple dies into a single unit. COB variants are also used in newer LED bulbs as in this case the substrate can be either glass, sapphire or sometimes regular phenolic.

With a transparent substrate the LED chips may be installed "upside down" shining through for higher outcoupling. Typically they are glued to the substrate with UV setting glue, interconnects attached, and the encapsulant and phosphor applied in a single step with a back reflective coating applied to channel light out of the device.

References

edit- ^ "How Chip-On-Boards are Made - learn.sparkfun.com". learn.sparkfun.com. Retrieved 2022-05-08.

- ^ a b John H. Lau, Chip On Board: Technology for Multichip Modules, Springer Science & Business Media, 1994 ISBN 0442014414 pages 1-3

- ^ "How Chip-On-Boards are Made - learn.sparkfun.com". learn.sparkfun.com. Retrieved 2022-05-08.

- ^ Nandivada, Venkat (2013-01-16). "Enhance Electronic Performance with Epoxy Compounds". Design World. Retrieved 2023-02-17.

- ^ Kelly, Joe (December 2004). "Improving Chip on Board Assembly". empf.com. Archived from the original on 2006-09-23.

- ^ Handbook on the Physics and Chemistry of Rare Earths: Including Actinides. Elsevier Science. 1 August 2016. p. 89. ISBN 978-0-444-63705-5.