A bipin or bi-pin (sometimes referred to as two-pin, bipin cap or bipin socket) is a type of lamp fitting. They are included in the IEC standard "IEC 60061 Lamp caps and holders together with gauges for the control of interchangeability and safety". They are used on many small incandescent light bulbs (especially halogen lamps), and for starters on some types of fluorescent lights.

Some sockets have pins placed closer together, preventing the low-power bulbs they use from being replaced by bulbs that are too high power, which may generate excessive heat and possibly cause a fire. These are sometimes called "mini-bipin". Where the terminals of the lamp are bent back onto the sides of the base of the bulb, this forms a wedge base, often used in small bulbs for automotive lighting.

The bi-pin base was invented by Reginald Fessenden for the 1893 World's Fair in Chicago.[citation needed] After Westinghouse won the contract to wire and illuminate the first electrified fair with AC instead of arch-rival Thomas Edison's DC, Edison and his General Electric company refused to allow his patented Edison screw-base bulbs to be used. Westinghouse overcame this by developing the bi-pin base for use at the fair. An incandescent electric lamp with a bi-pin base was patented by the Westinghouse (G. Westinghouse, Jr.) in 1895.[1][non-primary source needed]

Types

edit| Illustration | Designation | IEC 60061-1 sheet | Pin | Usage | |

|---|---|---|---|---|---|

| Pitch | Diameter | ||||

| G4 | 7004-72-3 | 4.0 mm | 0.65–0.75 mm | Small halogen quartz capsules of 5/10/20 watt and 6/12 volt AC and DC. | |

| GU4 | 7004-108-2 | 4.0 mm | 0.95–1.05 mm | MR11 and MR8 | |

| GY4 | 7004-72A-1 | 4.0 mm | 0.65–0.75 mm | ||

| GZ4 | 7004-67-3 | 4.0 mm | 0.95–1.05 mm | MR11 and MR8 | |

| G5 | 7004-52-7 | 5 mm | T4 and T5 fluorescent tubes | ||

| G5.3 | 7004-73-2 | 5.33 mm | 1.47–1.65 mm | ||

| G5.3-4.8 | 7004-126-1 | ||||

| GU5.3 | 7004-109-2 | 5.33 mm | 1.45-1.6 mm | ||

| GX5.3 | 7004-73A-2 | 5.33 mm | 1.45–1.6 mm | Round pins. MR16 and other small halogens of 20/35/50 watt and 12/24 volt. | |

| GY5.3 | 7004-73B-2 | 5.33 mm | — | Flat pins | |

| G6.35 | 7004-59-6 | 6.35 mm | 0.95–1.05 mm | ||

| GX6.35 | 7004-59-6 | 6.35 mm | 0.95–1.05 mm | ||

| GY6.35 | 7004-59-6 | 6.35 mm | 1.2–1.3 mm | Halogen various wattage (e.g. 50 W/100 W), various voltage (e.g. 12/24 V). Common for task lighting, landscape lighting. | |

| GZ6.35 | 7004-59A-3 | 6.35 mm | 0.95–1.05 mm | projector bulb | |

| G8 | — | 8.0 mm | 1.0 mm | Halogen 35–100 W 120-240 V | |

| GY8.6 | — | 8.0 mm | 1.25 mm | Halogen up to 100 W, 120 V | |

| G9 | 7004-129-3 | 9.0 mm | Halogen 120 V (US) / 230 V (EU), also used for LED lamps. | ||

| G9.5 | 7004-70-2 | 9.5 mm | 3.10–3.25 mm | Common for theatre use, several variants | |

| GU10 | 7004-121-2 | 10 mm | 5 mm | Twist-lock 120/230-volt MR16 halogen lighting of 35/50 watt, since the mid-2000s. Also used for compact fluorescents and LED lamps. | |

| GZ10 | 7004-120-1 | 10 mm | Twist-lock 120/230-volt MR16 halogen lighting of 35/50 watt, differs from GU10 by use of a dichroic reflector. GZ10 fixtures can use GU10 bulbs, but not vice versa. | ||

| G12 | 7004-63-2 | 12.0 mm | 2.35 mm | Used in theatre and single-end metal halide lamps. | |

| G13 | 7004-51-10 | 0.50 in (12.7 mm) | 0.093 in (2.35 mm) | Common T8, T10 and T12 fluorescent tubes. | |

| GX16d | "Mogul End Prong", common for theatre PAR lamps. | ||||

| G23 | 7004-69-1 | 23 mm | 2 mm | ||

| GU24 | 7004-78-5 | 24 mm | Twist-lock for self-ballasted compact fluorescents, since the 2000s. | ||

| G38 | 7004-76-1 | 38 mm | 11.1 mm | Mostly used for high-power theatre lamps. | |

| GX53 | 7004-142-2 | 53 mm | Twist-lock for puck-shaped under-cabinet compact fluorescents and LED lamps, since the 2000s. | ||

| GX70 | — | 70 mm | Twist-lock for puck-shaped compact fluorescents or LED lamps. | ||

The suffix after the G indicates the pin spread; the G dates to the use of Glass for the original bulbs. GU usually also indicates that the lamp provides a mechanism for physical support by the luminaire: in some cases, each pin has a short section of larger diameter at the end (sometimes described as a "peg" rather than a "pin"[2]); the socket allows the bulb to lock into place by twisting it; in others, the base of the lamp has a groove which can be held by a spring or clip.[3]

A lowercase "q" at the end of the designation indicates that it is a quad-pin base, with two bi-pin pairs. These are used with compact fluorescent tubes that plug into a light fixture that has a permanent ballast.

There are also double-ended halogen and fluorescent tubes with one pin at each end, and high-output fluorescents with recessed or shrouded contacts, which are not covered here.

-

Halogen lamps with GU4 (left) and G4 (right) bases

-

Halogen lamp with G6.35 base

-

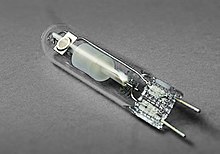

Metal halide lamp with G8.5 base

-

Halogen lamp with G9 looped-pin base

-

Halogen lamp with GU10 twist-lock base

See also

editReferences

edit- ^ *U.S. patent 543,280, incandescent electric lamp

- ^ Simon Brammer (28 March 2014). "Converting to LED lights: everything you need to know". The Guardian. Retrieved 20 November 2018.

- ^ "index". Osram.com. 2012-03-09. Archived from the original on April 29, 2011. Retrieved 2012-04-25.

External links

edit- Media related to Bipin at Wikimedia Commons

- Cross-reference for EU/US