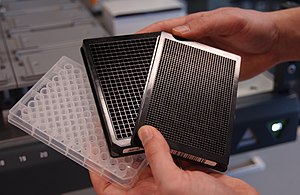

A microplate, also known as a microtiter plate, microwell plate or multiwell,[1] is a flat plate with multiple "wells" used as small test tubes. The microplate has become a standard tool in analytical research and clinical diagnostic testing laboratories. A very common usage is in the enzyme-linked immunosorbent assay (ELISA), the basis of most modern medical diagnostic testing in humans and animals.

A microplate typically has 6, 12, 24, 48, 96, 384 or 1536 sample wells arranged in a 2:3 rectangular matrix. Some microplates have been manufactured with 3456 or 9600 wells, and an "array tape" product has been developed that provides a continuous strip of microplates embossed on a flexible plastic tape.[2]

Each well of a microplate typically holds somewhere between tens of nanolitres[3][4][5][6] to several millilitres of liquid. They can also be used to store dry powder or as racks to support glass tube inserts. Wells can be either circular or square. For compound storage applications, square wells with close fitting silicone cap-mats are preferred. Microplates can be stored at low temperatures for long periods, may be heated to increase the rate of solvent evaporation from their wells and can even be heat-sealed with foil or clear film. Microplates with an embedded layer of filter material were developed in the early 1980s by several companies, and today, there are microplates for just about every application in life science research which involves filtration, separation, optical detection, storage, reaction mixing, cell culture and detection of antimicrobial activity.[7]

The enormous growth in studies of whole live cells has led to an entirely new range of microplate products which are "tissue culture treated" especially for this work. The surfaces of these products are modified using an oxygen plasma discharge to make their surfaces more hydrophilic so that it becomes easier for adherent cells to grow on the surface which would otherwise be strongly hydrophobic.

A number of companies have developed robots to specifically handle microplates. These robots may be liquid handlers which aspirate or dispense liquid samples from and to these plates, or "plate movers" which transport them between instruments, plate stackers which store microplates during these processes, plate hotels for longer-term storage, plate washers for processing plates, plate thermal sealers for applying heat seals, de-sealers for removing heat seals, or microplate incubators to ensure constant temperature during testing. Instrument companies have designed plate readers which can detect specific biological, chemical or physical events in samples stored in these plates. A specialized plate reader has also been developed which can perform quality control of microplate well contents, capable of identifying empty wells, filled wells and precipitate.[8]

Manufacture and composition

editThe most common manufacturing process is injection molding, using materials such as polystyrene, polypropylene and cyclo-olefin for different temperature and chemical resistance needs. Glass is also a possible material, and vacuum forming can be used with many other plastics such as polycarbonate.

Microplates are manufactured from a variety of materials:

- Polystyrene (PS) is the most common, and is used for high-clarity optical detection microplates. It can be coloured white by the addition of titanium dioxide for optical absorbance or luminescence detection or black by the addition of carbon for fluorescent biological assays. But, it has poor resistance to organic solvents. It also starts melting at around 80˚C, and thus cannot be autoclaved.[9]

- Polypropylene (PP) is used for the construction of plates subject to wide changes in temperature, such as storage at −80 °C and thermal cycling. It has excellent properties for the long-term storage of novel chemical compounds and high resistance to organic solvents. It can be sterilized by autoclaving at 121˚C.[9] Reportedly leachables including plasticizers (i.e. phtalates), whiteners, and heavy metals (cobalt) are more of a concern with PP versus PS plates.[9]

- Cyclo-olefins (COC) are now being used to construct microplates which transmit near-ultraviolet light, allowing applications like protein assays via absorbance measurements at 280 nm. But, COC has a poor resistance to organic solvents & is incompatible with high temperatures.

- Polycarbonate (PC) is cheap and easy to mould and has been used for disposable microplates for the polymerase chain reaction (PCR) method of DNA amplification.

- Glass or quartz is also, albeit less commonly & rather expensively, used to construct microplates for special applications that require extreme resistance to organic solvents and/or the surface properties of glass, or the ultraviolet C transmission capability of quartz.

Composite microplates, including filter bottom plates, solid phase extraction (SPE) plates, and even some advanced PCR plate designs, use multiple components and/or materials which are moulded separately and later assembled into a finished product. ELISA plates may now be assembled from twelve separate strips of eight wells, making it easier to only partially use a plate.

Formats and Standardization efforts

editMicroplates are produced with the same standardized footprint,[10][11] but using a variety of formats (see table below), materials (see above section), plate heights, numbers of wells, well shapes, and well bottom heights, with some of these characteristics being more varied between manufacturers than others (see below section).

| wells | volume (mL) | |

|---|---|---|

| number | arrangement | |

| 6 | 2×3 | 2 – 5 |

| 12 | 3×4 | 2 – 4 |

| 24 | 4×6 | 0.5 – 3 |

| 48 | 6×8 | 0.5 – 1.5 |

| 96 | 8×12 | 0.1 – 0.3 |

| 384 | 16×24 | 0.03 – 0.1 |

| 1536 | 32×48 | 0.005 – 0.015; Usage in UHTS (Ultra HTS) |

| 3456 | 48×72 | 0.001 – 0.005; Usage in UHTS (Ultra HTS). |

There are also less common 192- and 768-well plates.[12]

-

24-well

-

48-well

-

96-well

-

384-well

Standardization efforts

editAn attempt at standardizing microplates was made by the Society for Biomolecular Sciences with the ANSI-Standards (ANSI/SBS 1-2004, ANSI/SBS 2-2004, ANSI/SBS 3-2004, ANSI/SBS 4-2004).[13] These standards have been updated to and are now known as the ANSI SLAS standards.

Footprint & flange (standardized)

editThe ANSI SLAS microplate standards define a footprint, and a bottom flange geometry. These footprints & flanges are generally rigorously followed by all microplate manufacterers:

Corner notch

editAlthough a corner notch (aka chamfer) is shown at the A1 (top-left) corner in the ANSI SLAS drawings, and many microplates do implement this A1 corner notch, in actuality the "quantity and location of chamfers(s) is optional",[14][15] so in practice the presence or absence of corner notches at additional corners (i.e. the bottom-left) is a proprietary implementation which causes difficulties with accessory cross-compatibility such as with microplate lids that may also implement the matching corner notch.

Well position (standardized)

editThe well position is also standardized, but only for 96- , 384-, and 1536-well plates. These are generally well followed by manufacturers:

96-well plates have a 9 mm well-to-well spacing, 384-wells a 4.5 mm spacing, and 1536-wells a 2.25 mm spacing. A notable characteristic is that the well array is symmetrical when the plate is rotated 180˚ around its Z-axis (height axis). Therefore, scientific instruments which use microplates, can accept the plate in one of two rotated orientations - either "correct" or 180˚ rotated.

Other variants like 24-well plates, are not considered in the standard, but there is a de facto standard to implement to 24-wells by apply the same scaling factor as the 384- to 96-well transition, i.e. 24-wells have an 18 mm spacing.

Well shape

editNotably, the shape and diameter of the well is not standardized, and has several proprietary implementations. This causes difficulties with accessory cross-compatibility such as with microplate cap mats.

Wells within the microplate are available in different shapes:

- Round well

- Square well

Wells also have different geometries at the bottom of the well:

- F-Bottom: flat bottom (compatible with through-well optical plate reader measurements)

- V-Bottom: V-shaped bottom (conical for round wells, square pyramid for square wells; improves aspiration of low liquid volumes)

- U-Bottom: U-shaped bottom (half sphere; improves aspiration of low liquid volumes)

- C-Bottom: bottom with minimal rounded edges

Round wells in particular often come in a few diameters:

- 6.96 mm[18]

- 8.3 mm

Well Bottom Elevation

editThe most recent addition to the ANSI SLAS microplate standards was the inclusion of a well bottom standard. The standard however specifies definitions and test methods only, for the "Microplate Well Bottom Elevation (WBE)", "Well Bottom Elevation Variation (WBEV)", and "Intra-Well Bottom Elevation Variation (IWBEV)", but it does not state a preferred value or limits for those dimensional definitions. Therefore all well bottom heights are currently proprietary implementations without a clear de facto standard. This lack of standardization can cause difficulties with applications such as automated autosampler needle injection.

Standard microplate height

editThe height of a standard microplate is also defined, however this is sometimes not followed by manufacturers, even if they follow the footprint and flange standards.

Microplate variants with increased heights

editThere are also deep well microplates sometimes called "blocks". Unlike plates of normal height, the ANSI SLAS 2-2004 height standard,[23] does not define a standard height for deep well plates (blocks). Deepwell plates do typically follow a de facto standard height of 44 mm.

Reservoir plates are also commercially available.[24] Reservoir plates have columns of wells (as in 96-well, 24-well, etc. plates) that are fused into single wells, so that they provide additional volume for multichannel pipettes. Like deepwell plates or blocks, they often follow a de facto standard height of 44 mm.

Skirts

editMicroplates used for PCR are designed to have a notably thinner wall thickness than standard ANSI/SLAS microplates (to allow for better thermal conduction), and to come in a few different "skirt" types: full-skirt, half-skirt or semi-skirted, and unskirted or no-skirted. The skirt is analogous to the footprint & flange of the ANSI/SLAS standards, so while most full-skirt PCR microplates may be ANSI/SLAS compliant, other deviations such as semi-skirted or others, are not compliant ANSI/SLAS standards.

History

editThe earliest microplate was created in 1951 by a Hungarian, Dr. Gyula Takátsy, who machined six rows of 12 "wells" in Lucite.[12][25][26] Subsequently, Dr. John Louis Sever modified the Hungarian design into a 96-well plate, which he published in 1962.[27] However, common usage of the microplate began in the late 1980s when John Liner introduced a molded version. By 1990 there were more than 15 companies producing a wide range of microplates with different features. It was estimated that 125 million microplates were used in 2000 alone.[28] The word "Microtiter" is a registered trademark of Thermo Electron OY (U.S. Trademark 754,087.)

Other trade names for microplates include Viewplate and Unifilter (introduced in the early 1990s by Polyfiltronics and sold by Packard Instrument, which is now part of PerkinElmer).

In 1996, the Society for Biomolecular Screening (SBS), later known as Society for Biomolecular Sciences, began an initiative to create a standard definition of a microplate. A series of standards was proposed in 2003 and published by the American National Standards Institute (ANSI) on behalf of the SBS. The standards govern various characteristics of a microplate including well positioning (but not shape, depth, and diameter) as well as plate properties, which allows interoperability between microplates, instrumentation and equipment from different suppliers, and is particularly important in laboratory automation. In 2010, the Society for Biomolecular Sciences merged with the Association for Laboratory Automation (ALA) to form a new organisation, the Society for Laboratory Automation and Screening (SLAS). Henceforth, the microplate standards are known as ANSI SLAS standards.

See also

editReferences

edit- ^ "Medical scientific instruments". Archived from the original on 2011-02-06. Retrieved 2011-02-06.

- ^ Elaine May (2007-06-15). <date>/url=http://www.genengnews.com/articles/chtitem.aspx?tid=2136 "Array Tape for Miniaturized Genotyping". Genetic Engineering & Biotechnology News. Mary Ann Liebert, Inc. p. 22. Archived from the original on 2009-02-24. Retrieved 2008-07-06.

(subtitle) Processing hundreds of microplate equivalents without complex plate-handling equipment

- ^ Lindström, Sara; Eriksson, Malin; Vazin, Tandis; Sandberg, Julia; Lundeberg, Joakim; Frisén, Jonas; Andersson-Svahn, Helene (2009-01-01). "High-density microwell chip for culture and analysis of stem cells". PLOS ONE. 4 (9): e6997. Bibcode:2009PLoSO...4.6997L. doi:10.1371/journal.pone.0006997. ISSN 1932-6203. PMC 2736590. PMID 19750008.

- ^ Weibull, Emilie; Antypas, Haris; Kjäll, Peter; Brauner, Annelie; Andersson-Svahn, Helene; Richter-Dahlfors, Agneta (2014-09-01). "Bacterial nanoscale cultures for phenotypic multiplexed antibiotic susceptibility testing". Journal of Clinical Microbiology. 52 (9): 3310–3317. doi:10.1128/JCM.01161-14. ISSN 1098-660X. PMC 4313156. PMID 24989602.

- ^ Lindström, Sara; Larsson, Rolf; Svahn, Helene Andersson (2008-03-01). "Towards high-throughput single cell/clone cultivation and analysis". Electrophoresis. 29 (6): 1219–1227. doi:10.1002/elps.200700536. ISSN 0173-0835. PMID 18288779. S2CID 25258352.

- ^ Antypas, H.; Veses-Garcia, M.; Weibull, E.; Andersson-Svahn, H.; Richter-Dahlfors, A. (2018). "A universal platform for selection and high-resolution phenotypic screening of bacterial mutants using the nanowell slide". Lab on a Chip. 18 (12): 1767–1777. doi:10.1039/c8lc00190a. ISSN 1473-0197. PMC 5996734. PMID 29781496.

- ^ Inglin, Raffael C. (2015). "High-throughput screening assays for antibacterial and antifungal activities of Lactobacillus species". Journal of Microbiological Methods. 114 (July 2015): 26–29. doi:10.1016/j.mimet.2015.04.011. PMID 25937247.

- ^ Baillargeon P, Scampavia L, Einsteder R, Hodder P (2011). "Monitoring of HTS compound library quality via a high-resolution image acquisition and processing instrument". J Lab Autom. 16 (3): 197–203. doi:10.1016/j.jala.2011.02.004. PMC 3417353. PMID 21609702.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ a b c "Basic information on plastics". Enzyscreen. Retrieved 2024-11-01.

- ^ a b SLAS, ANSI. "ANSI SLAS 1-2004 - Footprint Dimensions for Microplates". Retrieved 20 April 2023.

- ^ a b SLAS, ANSI. "ANSI SLAS 1-2004 - Footprint Dimensions for Microplates" (PDF). Retrieved 20 April 2023.

- ^ a b Microarrays & microplates : applications in biomedical sciences. Ye, S. (Shu), 1961-, Day, Ian N. M. Oxford, UK: BIOS. 2003. ISBN 978-1-85996-074-5. OCLC 51032550.

{{cite book}}: CS1 maint: others (link) - ^ Society for Biomolecular Sciences (Hrsg.): Microplate Standards Working Group – Published Standards. retrieved am: 12 February 2009.

- ^ a b SLAS, ANSI. "ANSI SLAS 3-2004 - Bottom Outside Flange Dimensions". Retrieved 20 April 2023.

- ^ a b SLAS, ANSI. "ANSI SLAS 3-2004 - Bottom Outside Flange Dimensions" (PDF). Retrieved 20 April 2023.

- ^ SLAS, ANSI. "ANSI SLAS 4-2004 -Well Positions for Microplates". Retrieved 20 April 2023.

- ^ SLAS, ANSI. "ANSI SLAS 4-2004 - Well Positions for Microplates" (PDF). Retrieved 20 April 2023.

- ^ Bio-One, Greiner. "Customer Drawing - 96 Well Microplate, PP" (PDF). Retrieved 21 April 2023.

- ^ SLAS, ANSI. "ANSI SLAS 6-2012 - Well Bottom Elevation for Microplates". Retrieved 20 April 2023.

- ^ SLAS, ANSI. "ANSI SLAS 6-2012 - Well Bottom Elevation for Microplates" (PDF). Retrieved 20 April 2023.

- ^ SLAS, ANSI. "ANSI SLAS 2-2004 - Height Dimensions for Microplates". Retrieved 20 April 2023.

- ^ SLAS, ANSI. "ANSI SLAS 2-2004 - Height Dimensions for Microplates" (PDF). Retrieved 20 April 2023.

- ^ SLAS, ANSI. "Height Dimensions for Microplates" (PDF). Retrieved 20 April 2023.

- ^ "Reservoir Microplates". Agilent.

- ^ Farkas E. (27 July 1992). "Microtitrations in serology and virology – a citation-classic commentary on the use of spiral loops in serological and virological micro-methods by Takatsy, G." (PDF). Current Contents/Life Sciences (30): 10.

- ^ Takatsy G (1950). "Uj modszer sorozatos higitasok gyors es pontos elvegzesere" [A rapid and accurate method for serial dilutions]. Kiserl. Orvostud. 5: 393–7.

- ^ Sever, John Louis (1 March 1962). "Application of a Microtechnique to Viral Serological Investigations". The Journal of Immunology. 88 (3): 320–329. doi:10.4049/jimmunol.88.3.320.

- ^ Manns, Roy (1999). Microplate History (2 ed.).