graft macromolecule: A macromolecule with one or more species of block connected

to the main chain as side-chains, these side-chains having constitutional or configurational

features that differ from those in the main chain.

comb macromolecule: A macromolecule comprising a main chain with multiple

trifunctional branch points from each of which a linear side-chain emanates.Notes

1. If the subchains between the branch points of the main chain and the terminal

subchains of the main chain are identical with respect to constitution and degree

of polymerization, and the side chains are identical with respect to constitution

and degree of polymerization, the macromolecule is termed a ’’regular

comb macromolecule’’. 2. If at least some of the branch points are of functionality greater than three, the

macromolecule may be termed a ‘’brush macromolecule’’.

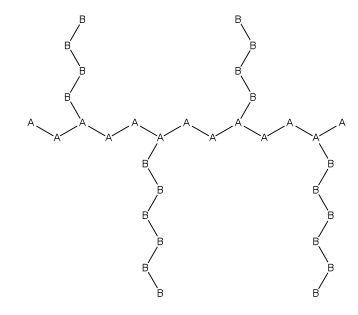

In polymer chemistry, graft polymers are segmented copolymers with a linear backbone of one composite and randomly distributed branches of another composite. The picture labeled "graft polymer" shows how grafted chains of species B are covalently bonded to polymer species A. Although the side chains are structurally distinct from the main chain, the individual grafted chains may be homopolymers or copolymers. Graft polymers have been synthesized for many decades and are especially used as impact resistant materials, thermoplastic elastomers, compatibilizers, or emulsifiers for the preparation of stable blends or alloys. One of the better-known examples of a graft polymer is a component used in high impact polystyrene, consisting of a polystyrene backbone with polybutadiene grafted chains.

General properties

editGraft copolymers are a branched copolymer where the components of the side chain are structurally different than that of the main chain. Graft copolymers containing a larger quantity of side chains are capable of wormlike conformation, compact molecular dimension, and notable chain end effects due to their confined and tight fit structures.[1] The preparation of graft copolymers has been around for decades. All synthesis methods can be employed to create general physical properties of graft copolymers. They can be used for materials that are impact resistant, and are often used as thermoplastics elastomers, compatibilizers or emulsifiers for the preparation of stable blends or alloys.[2] Generally, grafting methods for copolymer synthesis results in materials that are more thermostable than their homopolymer counterparts.[3] There are three methods of synthesis, grafting to, grafting from, and grafting through, that are used to construct a graft polymer.[4]

Synthesis methods

editThere are many different approaches to synthesizing graft copolymers. Usually they employ familiar polymerization techniques that are commonly used such as atom transfer radical polymerization (ATRP), ring-opening metathesis polymerization (ROMP), anionic and cationic polymerizations, and free radical living polymerization. Some other less common polymerization include radiation-induced polymerization,[5] ring-opening olefin metathesis polymerization,[6] polycondensation reactions,[7] and iniferter-induced polymerization.[8]

Grafting to

editThe grafting to method involves the use of a backbone chain with functional groups A that are distributed randomly along the chain.[9] The formation of the graft copolymer originates from the coupling reaction between the functional backbone and the end-groups of the branches that are reactive. These coupling reactions are made possible by modifying the backbone chemically.[10] Common reaction mechanisms used to synthesize these copolymers include free-radical polymerization, anionic polymerization, atom-transfer radical-polymerization, and living polymerization techniques.

Copolymers that are prepared with the grafting-to method often utilize anionic polymerization techniques. This method uses a coupling reaction of the electrophilic groups of the backbone polymer and the propagation site of an anionic living polymer. This method would not be possible without the generation of a backbone polymer that has reactive groups. This method has become more popular with the rise of click chemistry. A high yield chemical reaction called atom transfer nitroxide radical coupling chemistry is for the grafting-to method for polymerization.

Grafting from

editIn the grafting-from method, the macromolecular backbone is chemically modified in order to introduce active sites capable of initiating functionality. The initiating sites can be incorporated by copolymerization, can be incorporated in a post-polymerization reaction, or can already be a part of the polymer.[10] If the number of active sites along the backbone participates in the formation of one branch, then the number of chains grafted to the macromolecule can be controlled by the number of active sites. Even though the number of grafted chains can be controlled, there may be a difference in the lengths of each grafted chain due to kinetic and steric hindrance effects.[9]

Grafting from reactions have been conducted from polyethylene, polyvinylchloride, and polyisobutylene. Different techniques such as anionic grafting, cationic grafting, atom-transfer radical polymerization, and free-radical polymerization have been used in the synthesis of grafting from copolymers.

Graft copolymers that are employed with the grafting-from method are often synthesized with ATRP reactions and anionic and cationic grafting techniques.

Grafting through

editThe grafting through, also known as the macromonomer method, is one of the simpler ways of synthesizing a graft polymer with well defined side chains.[10] Typically a monomer of a lower molecular weight is copolymerized with free radicals with an acrylate functionalized macromonomer. The ratio of monomer to macromonomer molar concentrations as well as their copolymerization behavior determines the number of chains that are grafted. As the reaction proceeds, the concentrations of monomer to macromonomer change causing random placement of branches and formation of graft copolymers with different number of branches. This method allows for branches to be added heterogeneously or homogeneously based on the reactivity ratio of the terminal functional group on the macromolecular to the monomer.[11] The difference in distribution of grafts has significant effects on the physical properties of the grafted copolymer. Polyethylene, polysiloxanes and poly(ethylene oxide) are all macromonomers that have been incorporated in a polystyrene or poly(methyl acrylate) backbone.

The macromonomer (grafting through) method can be employed using any known polymerization technique. Living polymerizations give special control over the molecular weight, molecular weight distribution, and chain-end functionalization.

Applications

editGraft copolymers became widely studied due to their increased number of applications like in drug delivery vehicles, surfactants, water filtration, rheology modifiers, etc.[12] It is their unique structures relative to other copolymers such as alternating, periodic, statistical, and block copolymers.

Some common applications of graft copolymers include:

- Membranes for the separation of gases or liquids[13]

- Hydrogels[14]

- Drug deliverers[15]

- Thermoplastic elastomers[16]

- Compatibilizers for polymer blends[17]

- Polymeric emulsifiers [18]

- Impact resistant plastics

High impact polystyrene

editHigh impact polystyrene (HIPS) was discovered by Charles F. Fryling in 1961.[19] HIPS is a low cost, plastic material that is easy to fabricate and often used for low strength structural applications when impact resistance, machinability, and low cost are required. Its major applications include machined prototypes, low-strength structural components, housings, and covers.[20] In order to produce the graft polymer, polybutadiene (rubber) or any similar elastomeric polymer is dissolved in styrene and polymerized. This reaction allows for two simultaneous polymerizations, that of styrene to polystyrene and that of the graft polymerization of styrene-rubber.[19] During commercial use, it can be prepared by graft copolymerization with additional polymer to give the product specific characteristics. The advantages of HIPS includes:[20]

- FDA compliant

- Good impact resistance

- Excellent machinability

- Good dimensional stability

- Easy to paint and glue

- Low cost

- Excellent aesthetic qualities

New properties as a result of grafting

editBy grafting polymers onto polymer backbones, the final grafted copolymers gain new properties from their parent polymers. Specifically, cellulose graft copolymers have various different applications that are dependent on the structure of the polymer grafted onto the cellulose.[21] Some of the new properties that cellulose gains from different monomers grafted onto it include:

- Absorption of water

- Improved elasticity

- Hydrophilic/Hydrophobic character

- Ion-exchange

- Dye adsorption capabilities[22]

- Heat Resistance

- Thermosensitivity[23]

- pH sensitivity[24]

- Antibacterial effect[25]

These properties give new application to the ungrafted cellulose polymers that include:

- Medical body fluid absorbent materials[26]

- Enhanced moisture absorbing ability in fabrics[27]

- Permselective membranes[28]

- Stronger nucleating properties than ungrafted cellulose, and adsorption of hazardous contaminants like heavy metal ions or dyes from aqueous solutions by temperature swing adsorption[23]

- Sensors and optical materials[29]

- Reducing agents for various carbonyl compounds[30]

References

edit- ^ Feng, Chun; Li, Yongjun; Yang, Dong; Hu, Jianhua; Zhang, Xiaohuan; Huang, Xiaoyu (2011). "Well-defined graft copolymers: from controlled synthesis to multipurpose applications". Chemical Society Reviews. 40 (3): 1282–95. doi:10.1039/b921358a. PMID 21107479.

- ^ Matyjaszewski, Krzysztof. "Graft Copolymers". Retrieved 14 March 2014.

- ^ Pearce, Eli M. (May 1987). "New commercial polymers 2, by Hans-George Elias and Friedrich Vohwinkel, Gordon and Breach, New York, 1986, 508 pp. Price: $90.00". Journal of Polymer Science Part C: Polymer Letters. 25 (5): 233–234. doi:10.1002/pol.1987.140250509.

- ^ al.], Volker Abetz ... [et (2005). Encyclopedia of polymer science and technology (Wird aktualisiert. ed.). [Hoboken, N.J.]: Wiley-Interscience. ISBN 9780471440260.

- ^ Hegazy, El-Sayed A.; Dessouki, Ahmed M.; El-Sawy, Naeem M.; Abd El-Ghaffar, Mahmoud A. (February 1993). "Radiation-induced graft polymerization of acrylic acid onto fluorinated polymers. II. Graft copolymer–metal complexes obtained by radiation grafting onto poly(tetrafluoroethylene-ethylene) copolymer". Journal of Polymer Science Part A: Polymer Chemistry. 31 (2): 527–533. Bibcode:1993JPoSA..31..527H. doi:10.1002/pola.1993.080310225.

- ^ Grutke, Stefan; Hurley, James H.; Risse, Wilhelm (August 1994). "Poly(phenylene oxide) macromonomers for graft copolymer synthesis via ring-opening olefin metathesis polymerization". Macromolecular Chemistry and Physics. 195 (8): 2875–2885. doi:10.1002/macp.1994.021950817.

- ^ Eisenbach, Claus D.; Heinemann, T. (July 1995). "Synthesis and Characterization of Graft Copolymers with Molecularly Uniform Urethane-Based Side Chains with Special Structural Elements". Macromolecules. 28 (14): 4815–4821. Bibcode:1995MaMol..28.4815E. doi:10.1021/ma00118a006.

- ^ Yamashita, K.; Ito, K.; Tsuboi, H.; Takahama, S.; Tsuda, K.; Otsu, T. (5 November 1990). "Graft copolymerization by iniferter method; structural analyses of graft copolymer by glass transition temperature". Journal of Applied Polymer Science. 40 (910): 1445–1452. doi:10.1002/app.1990.070400903.

- ^ a b Hadjichristidis, N., S. Pispas, H. Iatrou, and D. J. Lohse. "Graft Copolymers." Graft Copolymers. John Wiley and Sons Inc, 15 July 2002. Web. 14 Feb. 2014.

- ^ a b c Matyjaszewski, Krzysztof. "Graft Copolymers". Carnegie Mellon. Retrieved 14 February 2014.

- ^ Ito, Koichi; Hiroyuki Tsuchida; Akio Hayashi; Toshiaki Kitano (1985). "Reactivity of Poly(ethylene oxide) Macromonomers in Radical Copolymerization". Polymer Journal. 17 (7): 827–839. doi:10.1295/polymj.17.827.

- ^ Gupta, Srishti; Singh, Pummy; Moghadas, Babak; Grim, Bradley J.; Kodibagkar, Vikram D.; Green, Matthew D. (2020-05-08). "Synthesis of PEG and Quaternary Ammonium Grafted Silicone Copolymers as Nanoemulsifiers". ACS Applied Polymer Materials. 2 (5): 1856–1864. doi:10.1021/acsapm.0c00103. S2CID 216443242.

- ^ Nagase, Yu; Naruse, Akira; Matsui, Kiyohide (January 1990). "Chemical modification of polysulphone: 2. Gas and liquid permeability of polysulphone/polydimethylsiloxane graft copolymer membranes". Polymer. 31 (1): 121–125. doi:10.1016/0032-3861(90)90361-2.

- ^ Dualeh, Abdulkadir J.; Steiner, Carol A. (January 1991). "Bulk and microscopic properties of surfactant-bridged hydrogels made from an amphiphilic graft copolymer". Macromolecules. 24 (1): 112–116. Bibcode:1991MaMol..24..112D. doi:10.1021/ma00001a018.

- ^ MURAMATSU, Nobuhiro; YOSHIDA, Yasushi; KONDO, Tamotsu (1990). "Possible application of polyamine graft copolymer to targeting drug delivery". Chemical & Pharmaceutical Bulletin. 38 (11): 3175–3176. doi:10.1248/cpb.38.3175. PMID 2085903.

- ^ Eisenbach, Claus D.; Heinemann, Torsten (August 1995). "Thermoplastic graft copolymer elastomers with chain-folding or bifurcated side chains". Macromolecular Chemistry and Physics. 196 (8): 2669–2686. doi:10.1002/macp.1995.021960818.

- ^ Se¸k, Danuta; Kaczmarczyk, Bożena (June 1997). "Investigations of graft copolymer compatibilizers for blends of polyethylene and liquid crystalline polyester: 1. FT i.r. study". Polymer. 38 (12): 2925–2931. doi:10.1016/S0032-3861(96)00813-0.

- ^ Gupta, Srishti; Singh, Pummy; Moghadas, Babak; Grim, Bradley J.; Kodibagkar, Vikram D.; Green, Matthew D. (2020-05-08). "Synthesis of PEG and Quaternary Ammonium Grafted Silicone Copolymers as Nanoemulsifiers". ACS Applied Polymer Materials. 2 (5): 1856–1864. doi:10.1021/acsapm.0c00103. S2CID 216443242.

- ^ a b Fryling, Charles. "High Impact Polystyrene". Patent. Koppers Co Inc. Retrieved 14 February 2014.

- ^ a b Plastics International. "(HIPS) High Impact Polystyrene" (PDF). Archived from the original (PDF) on 22 February 2014. Retrieved 14 February 2014.

- ^ Kalia, Susheel; Sabaa, M. W., eds. (2013). Polysaccharide based graft copolymers (1., 2013 ed.). Heidelberg: Springer. ISBN 9783642365652.

- ^ Waly, A.; Abdel-Mohdy, F. A.; Aly, A. S.; Hebeish, A. (27 June 1998). "Synthesis and characterization of cellulose ion exchanger. II. Pilot scale and utilization in dye-heavy metal removal". Journal of Applied Polymer Science. 68 (13): 2151–2157. doi:10.1002/(SICI)1097-4628(19980627)68:13<2151::AID-APP11>3.0.CO;2-2.

- ^ a b Xie, Jiangbing; Hsieh, You-Lo (25 July 2003). "Thermosensitive poly(n-isopropylacrylamide) hydrogels bonded on cellulose supports". Journal of Applied Polymer Science. 89 (4): 999–1006. doi:10.1002/app.12206.

- ^ Wang, Deqian; Tan, Junjun; Kang, Hongliang; Ma, Lin; Jin, Xin; Liu, Ruigang; Huang, Yong (February 2011). "Synthesis, self-assembly and drug release behaviors of pH-responsive copolymers ethyl cellulose-graft-PDEAEMA through ATRP". Carbohydrate Polymers. 84 (1): 195–202. doi:10.1016/j.carbpol.2010.11.023.

- ^ Lee, Sang Beom; Koepsel, Richard R.; Morley, Scott W.; Matyjaszewski, Krzysztof; Sun, Yujie; Russell, Alan J. (May 2004). "Permanent, Nonleaching Antibacterial Surfaces. 1. Synthesis by Atom Transfer Radical Polymerization". Biomacromolecules. 5 (3): 877–882. doi:10.1021/bm034352k. PMID 15132676.

- ^ Toledano-Thompson, T.; Loría-Bastarrachea, M.I.; Aguilar-Vega, M.J. (October 2005). "Characterization of henequen cellulose microfibers treated with an epoxide and grafted with poly(acrylic acid)". Carbohydrate Polymers. 62 (1): 67–73. doi:10.1016/j.carbpol.2005.06.024.

- ^ Mondal, Md. Ibrahim H.; Uraki, Yasumitsu; Ubukata, Makoto; Itoyama, Koki (18 March 2008). "Graft polymerization of vinyl monomers onto cotton fibres pretreated with amines". Cellulose. 15 (4): 581–592. doi:10.1007/s10570-008-9210-z. S2CID 94521304.

- ^ Nishioka, Noboru; Watase, Keiji; Arimura, Keiji; Kosai, Kouichi; Uno, Masakuni (December 1984). "Permeability through Cellulose Membranes Grafted with Vinyl Monomers in a Homogeneous System I. Diffusive Permeability through Acrylonitrile Grafted Cellulose Membranes". Polymer Journal. 16 (12): 867–875. doi:10.1295/polymj.16.867.

- ^ Tang, Xinde; Gao, Longcheng; Fan, Xinghe; Zhou, Qifeng (1 May 2007). "Controlled grafting of ethyl cellulose with azobenzene-containing polymethacrylates via atom transfer radical polymerization". Journal of Polymer Science Part A: Polymer Chemistry. 45 (9): 1653–1660. Bibcode:2007JPoSA..45.1653T. doi:10.1002/pola.21932.

- ^ Dhiman, Poonam K.; Kaur, Inderjeet; Mahajan, R. K. (5 April 2008). "Synthesis of a cellulose-grafted polymeric support and its application in the reductions of some carbonyl compounds". Journal of Applied Polymer Science. 108 (1): 99–111. doi:10.1002/app.27423.